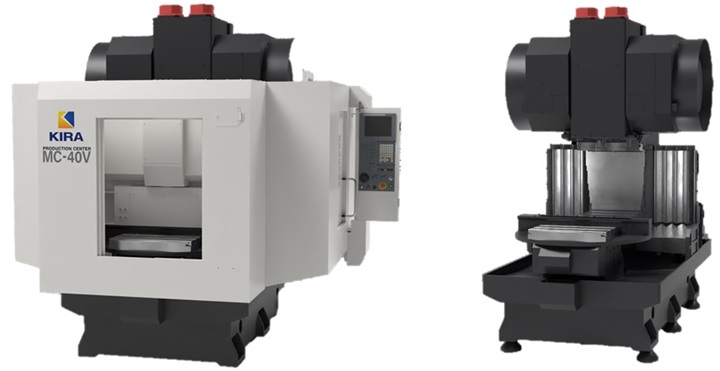

Ultra-high productive twin spindle machine revolutionizing the production line

Two workpieces machining in one cycle with two spindles on one machine

Twice the production capacity compared to single spindle

- Ultra-high productive machining center with two spindles on one machine

- Reduce the number of equipment units to use floor space efficiently

- Save total cost of fixtures, rotary tables, etc.

Features

【Productivity】

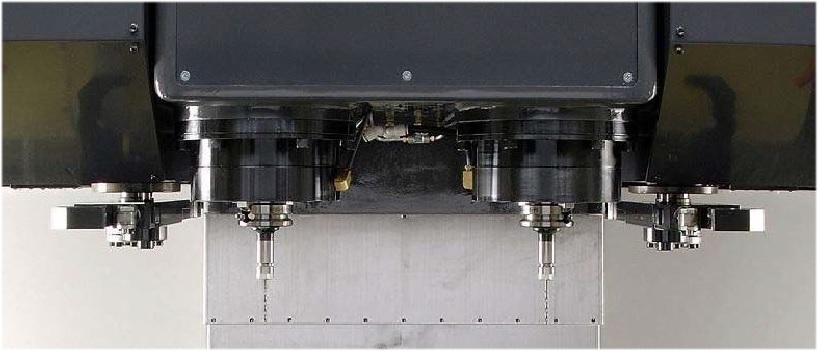

Twin spindle machine with two spindles on one machine

Machining two workpiece at the same time enables double productivity per one machine.

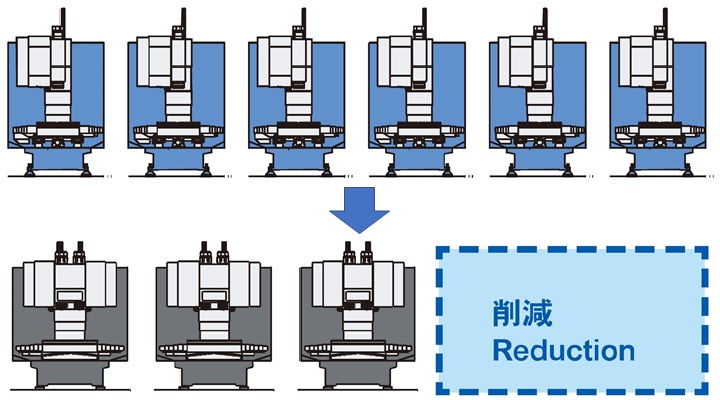

【Saving of total cost】

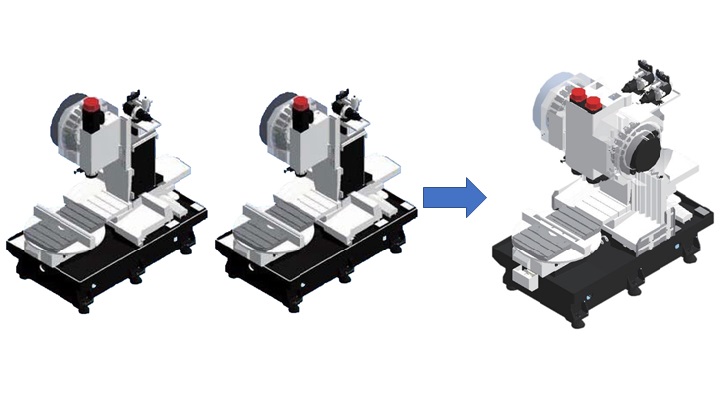

Reduction of the number of machines

Two units are condensed into one.

Saving of floor space

Shortened line lengths to use floor space efficiently.

Saving investment cost

Fixtures, rotary tables, coolant tanks, etc. can also be reduced, resulting in total investment cost savings.

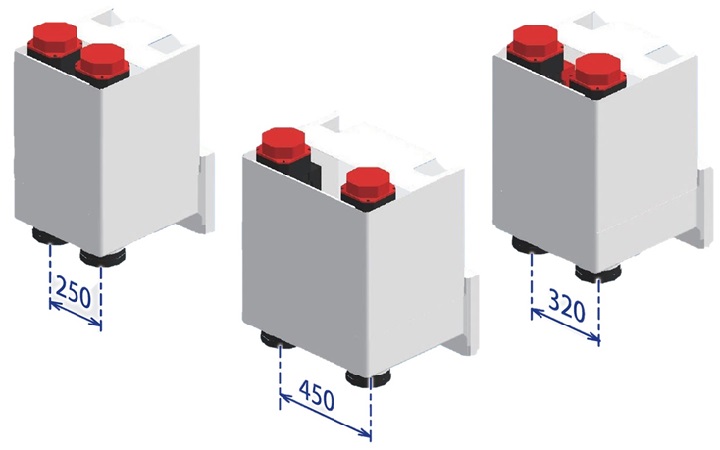

【Various lineup】

Distance between spindles

We line up three different distance between spindles to match the size of workpieces.

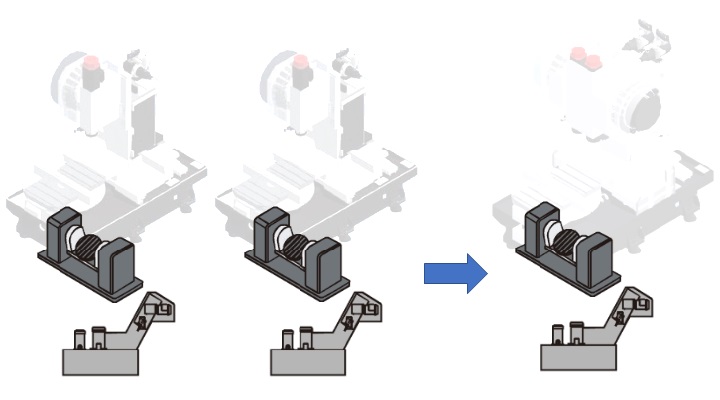

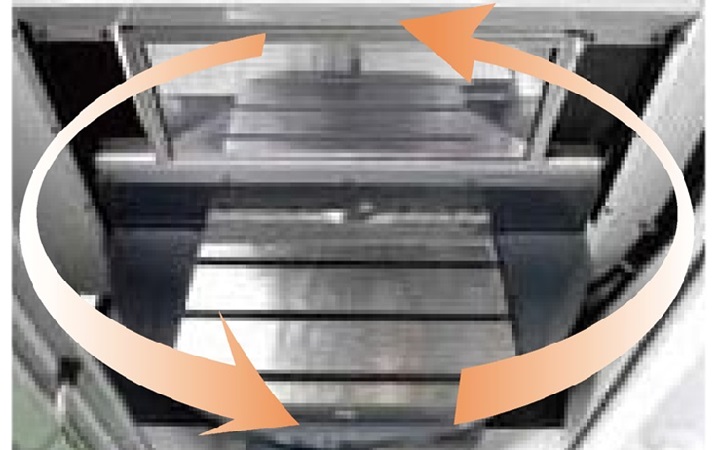

Pallet changer

Curvic coupling type pallet changer (2API) is available as an option for high productivity.

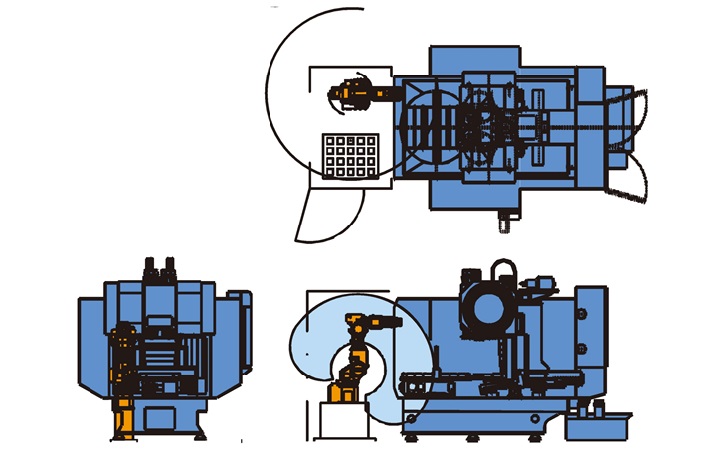

Suitable for automation

We flexibly support automation with gantry loaders and robots.

【Specifications】 |

||

| Capacity | X-axis stroke | 500mm |

| Y-axis stroke |

350mm |

|

| Z-axis stroke | 400mm | |

| Table | Table size | Standard:900mm x 400mm |

2API type:600mm x 350mm |

||

| Max. load capacity | Standard:500kg (uniform load) | |

2API type:100kg + 100kg (uniform load) |

||

| Spindle | Spindle speed | 10HP type:160-8000min-1 (7.5/5.5kW) |

10CB type:160-12000min-1 (7.5/5.5kW) |

||

20HP type:160-8000min-1 (15/11/7.5kW) |

||

| Taper | 7/24 taper No.40 | |

| Feed rate | Rapid traverse (X,Y,Z) | 36m/min |

| ATC | Tool shank | BT40 |

| No. of tools | 20 tools + 20 tools | |

| Machine dimension | Machine height | 2691mm |

| Floor space | Standard:2400mm x 3020mm | |

2API type:2400mm x 3500mm |

||

| Mass of machine | Standard:約5000kg | |

2API type:約5500kg |

||