KN-40Hb Aluminum Extrusion Machining

KN-40Hb Aluminum Extrusion Machining

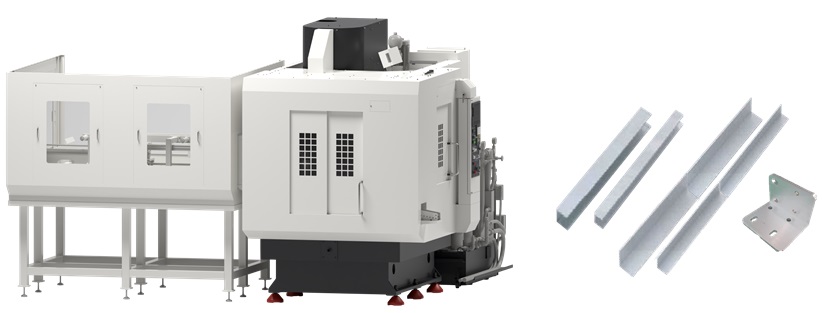

Process integration of machining aluminum extrusion material

Complete automation from loading the material to machining process and cutting !

Ultra-high productive machining center

This one single machine integrates process of machining aluminum extrusion. It is complete automated and ultra-high productive machining center. The aluminum extrusion which are difficult to control in the process such as aircraft / aerospace parts and EV parts, can be completely automated from loading, machining, cutting, to discharge. Installing stockers on the loading and unloading sides enables unattended long operation.

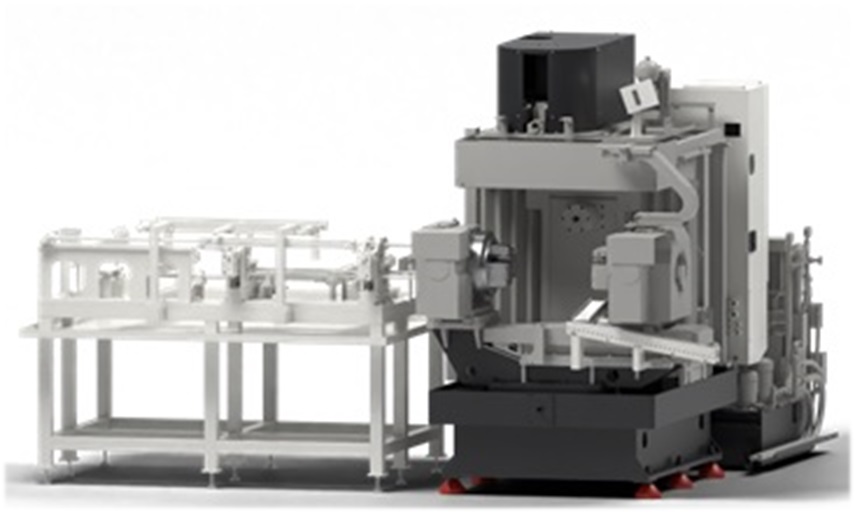

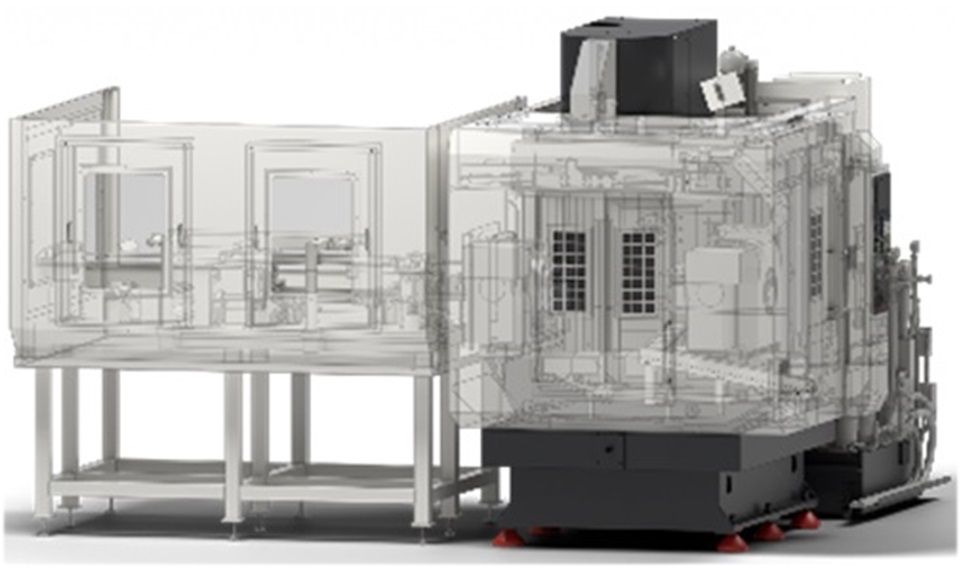

The basic system of the machine for aluminum extrusion

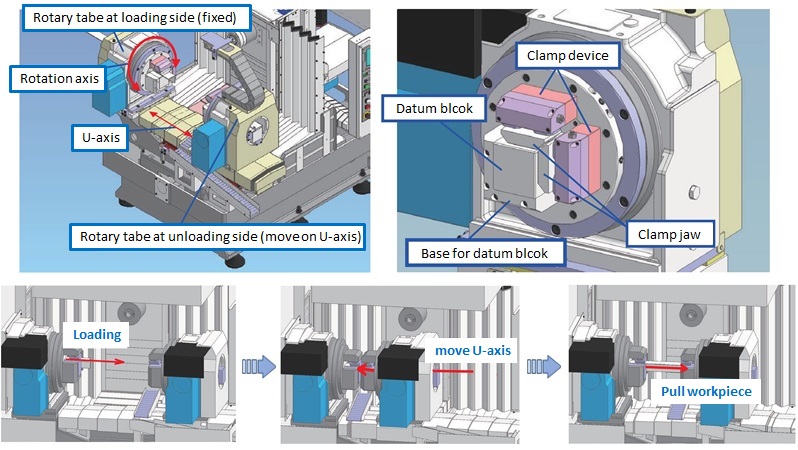

The base machine is equipped with two large rotary tables of Φ430 mm facing each other, enabling synchronized rotating motion of the two tables. The rotary table on the unloading side is installed on the U axis, which slides parallel to the X axis, allowing the workpiece to be pulled or chucked at both ends of the workpiece at any desired length. A pneumatically controlled clamping device is provided as standard equipment for clamping workpieces. The machine is also equipped with a mounting base for a workpiece clamping datum block, so that machining of aluminum extrusion can be easily started by simply preparing a datum block that matches the workpiece shape and a clamping jaw.

Further reduction of running costs in combination with automation

Installing stockers on the loading and unloading sides enables unattended long operation. Workpieces set in the stocker are automatically loaded into the machine and clamped to the rotary table. After machining the end faces, etc., as required, a rotary table installed on the opposite side of the loading side approaches the workpiece and pulls it out, and the two rotary tables clamp both ends of the workpiece for machining. If necessary, the workpiece is cut and processed on the opposite end face, or cut by a separately installed metal saw, etc., and then the workpiece is discharged from the machine. This operation is repeated until there is no more material left.