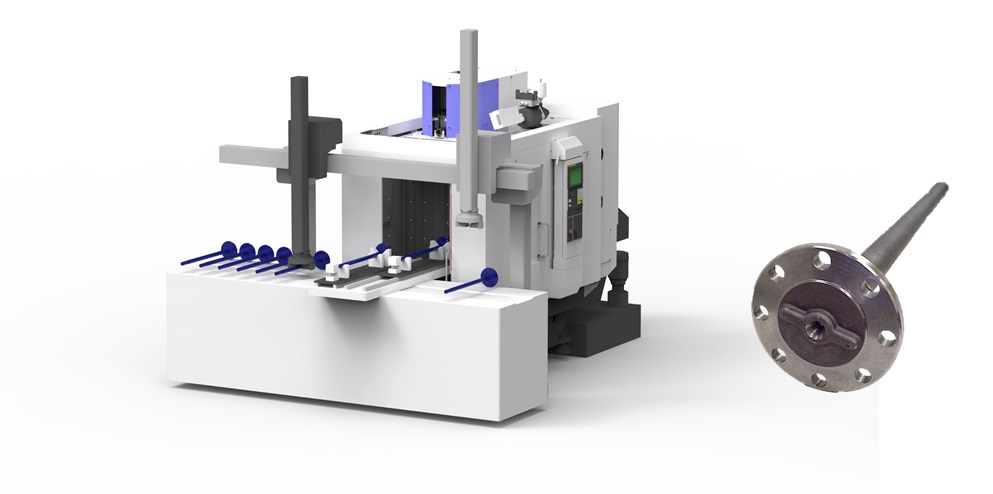

KN-40Hb Horizontal machine for Axle shaft machining

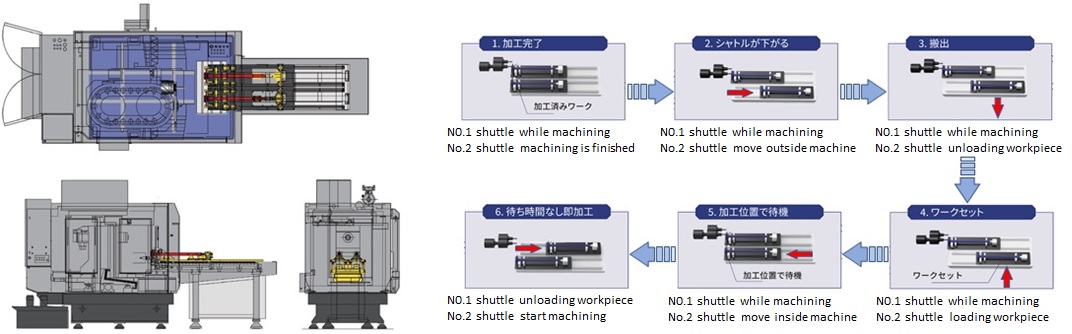

Double shuttle system equipped

Zero seconds for loading/unloading workpieces!

Ultra-high productive machining center

End-face machining of axle shafts and other long shafts, which is done on a special purpose machine, is performed on a small horizontal machining center. The double shuttle system reduces the time required for loading/unloading workpieces to zero seconds! This is an ultra-high productive machining center that reduces wasted time to the limit.

What is double shuttle system?

The fixture itself is installed on a shuttle, and after machining, the shuttle moves outside the machine for workpiece loading/unloading. By having two shuttles into one machine, one shuttle can be machining inside the machine while the other shuttle is outside the machine for workpiece loading/unloading. With zero second loading/unloading time, the machine always continues to produce parts.

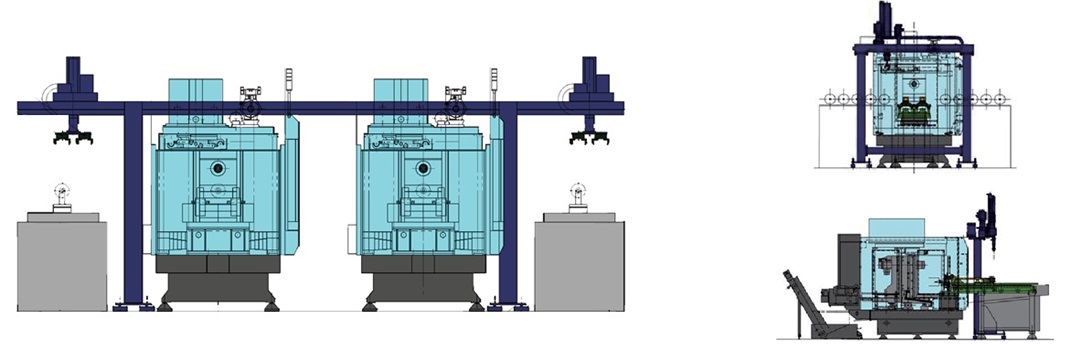

Further reduction of running costs in combination with automation

We flexibly support various automation tools such as gantry loaders and robots. In combination with Kira’s original machine-integrated gantry loader and CNC controlled 3-axis robot, we can help you achieve an automated production line with higher operability.