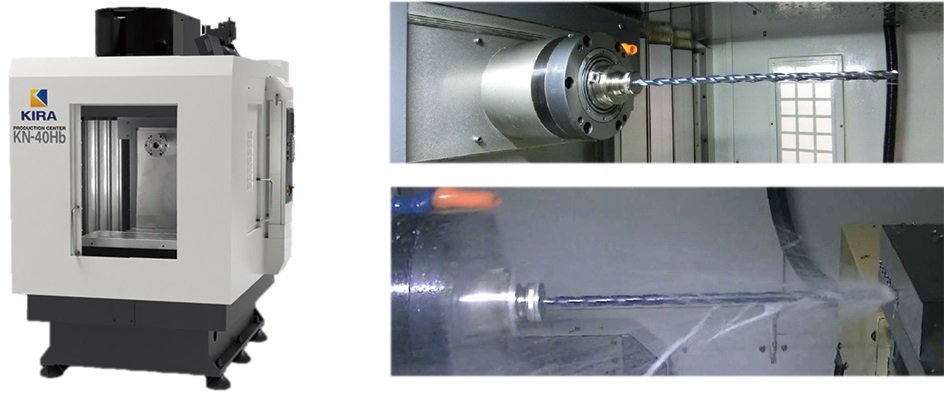

KN-40Hb for Shaft deep hole machining

Non-step 30D deep hole machining by machining center

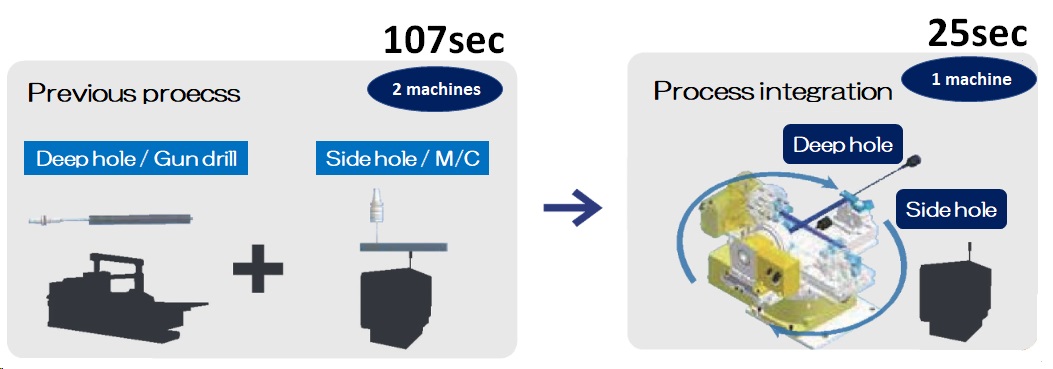

Process integration from special purpose machine!

High productive machining center for deep hole of shaft parts

Deep hole machining of shafts, which is done on a special purpose machine, is performed on a small horizontal machining center. Using normal available long drill, non-step machining and high cutting feed can significantly shorten cycle time. By integrating hole machining on the side of the shaft also into one machine, we are able to simultaneously reduce the number of equipment and achieve high productivity through process integration.

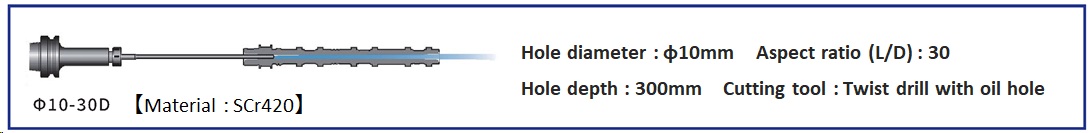

Target workpiece

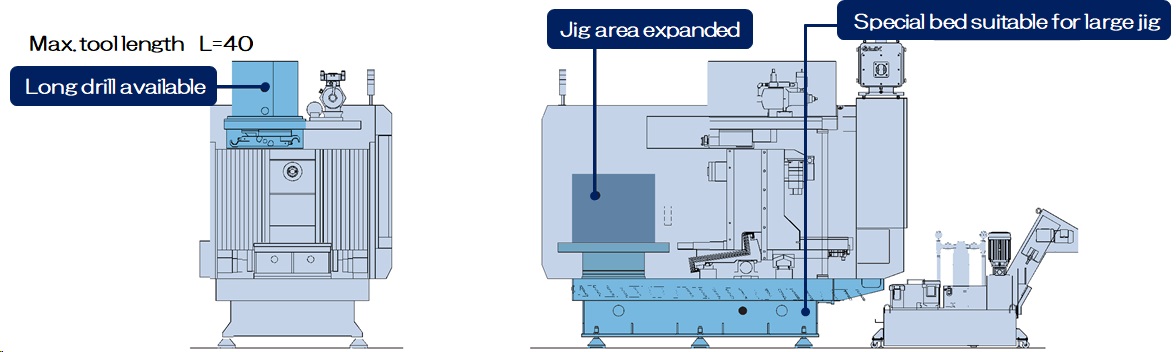

Special specification for deep hole machining

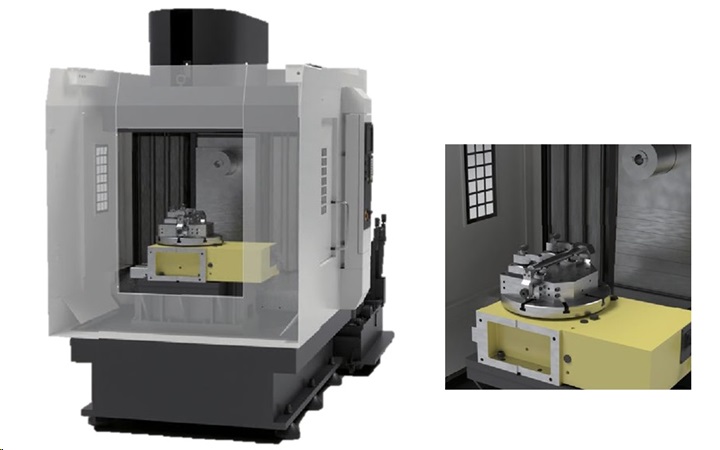

The jig area has been expanded with special bed suitable for large jig.

In addition, in order to enable to use long drill for deep hole machining, the ATC has been improved to have maximum tool length of 400mm.

Improve productivity with high-speed machining 5 times faster than gun drill machine.

Machining example

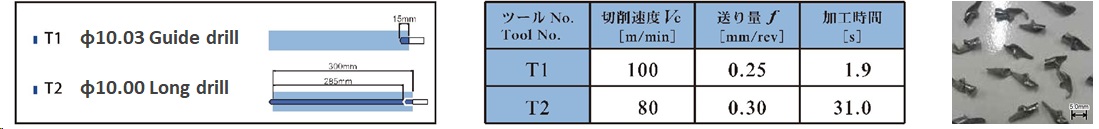

Cutting Tool / Cutting condition

Integrate processes into one machining center, significantly reducing investment costs

Case example

#40 Horizontal machining center

KN-40Hb

・Coolant through the spindle / max. 7MPa

・Long drill available

・Max. tool length 400mm

・Special bed suitable for large jig

・Jig area expanded

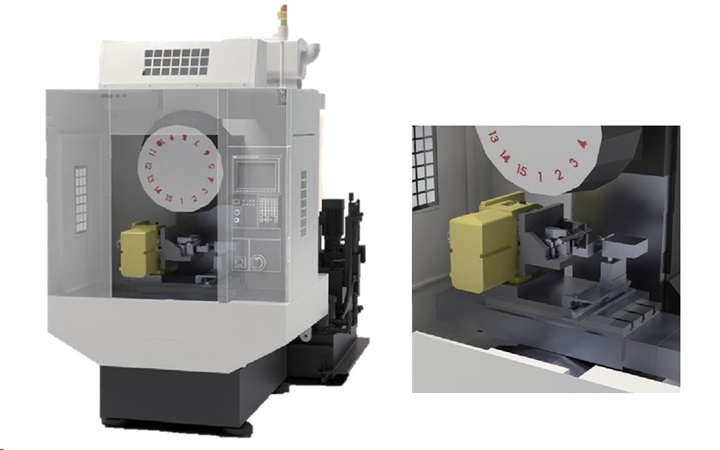

#30 Vertical machining center

PCV-30

・Coolant through the spindle / max. 7MPa

・Column riser